Products

Product Categories

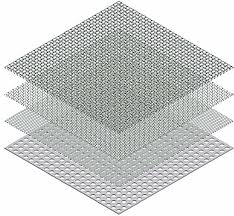

Woven Filters

Polymers

- Polyster

- Polypropelyne

- Nylon-6

- Nylon-6.6

- Aramide

- Cotton

- P/C Blended

- Antistatic Like Carbon

- SS Fiber

Weaves

- Plain

- Twill

- Drill

- BKT

- Satin

- Multi Layer DLW

Width, GSM and Pore size

- 80 CMS to 320 CMS

- 250 GSM to 800 GSM

- 0.1 Micron to 2000 Micron

Processes

- Scoured

- Heat Set

- Calendared

- Specialized Coating

- As per requirements

- Hard Finish

- OWR Finish

Non Woven Filters

Fibers

- Polyster

- Polypropelyne

- M-Aramide

- PPS

- Home-Polymer Acrylic

- Co-Polymer Acrylic

- Polyamide

Range of GSM

- 350 GSM to 800 GSM

- With or without reinforcement of scream fabric

- Scream reinforcement with AST or without AST

Processes

- Heat Set / One side calendared

- Heat Set / Both side calendared

- Heat Set / One or Both side singed

- PTFE Coating

- PTFE Lamination

- OWR Finish

- Anti Static Finish

Technical Textile

We also provide technical expertise for textile industrial solutions. Please contact us for more information.

Product Listing

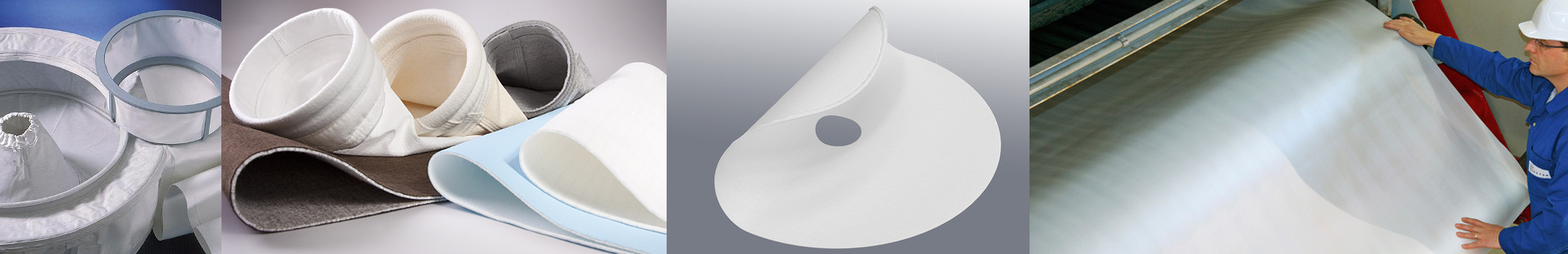

Dust Collection Bags

For optimum filtration Fabrics, we manufactures high quality dust collection conventional bags. We offer a wide range of filter bags that are manufactured from quality materials and are in conformation with the international quality standards. These filter bags are widely acknowledged in the market for high performance and durability. Our dust collection conventional bags are made from very technically and precisely selected media as per the process industry. These bags are more effectual in minimizing dust emission level as per requirement of industries.

We provide conventional dust collection filter bags from:

- Polypropylene Woven Fabric & Non- woven Needle felt for temperature up to 90 degree C.

- Polyester, Acrylic & Homo Polymer Acrylic Non-woven Needle felt for temperature up to 150 degree C.

- Ryton & Non-woven Needle felt for temperature up to 210 degree C.

- P84�Non-woven Needle felt for temperature up to 240 degree C.

- Woven Glass Fiber Filter bags for temperature up to 300 degree C.

- PTFE�Non-woven Needle felt for temperature up to 300 degree C.�

- Polyester and Cotton Woven Filter Bags for temperature up to 150 degree C.

Advantages of Bag Filter System:

- Low Maintenance Cost

- Practical Efficiency Very High

- Possibility of Heat Recovery Very Good

- Effectiveness Not Affected By Gas-dust Composition

Applications:

- Cement Industries

- Ferrous Metal and Non Ferrous Metal Industries

- Ferrous Alloys Plants

- Food Industries

- Chemicals and Pharmaceuticals Plants

- Wood Working Industries & Saw Mill

- Agro Chemicals & Fertilizers Plant

- Coal base� Lignite base Boilers Units

- Thermal Power Plants & Captive Power Plants

- Original Equipment Manufacturers

- Shot Blasting Units & Foreign Plants

- Petrochemicals Refineries

- Various Engineering Plants etc.

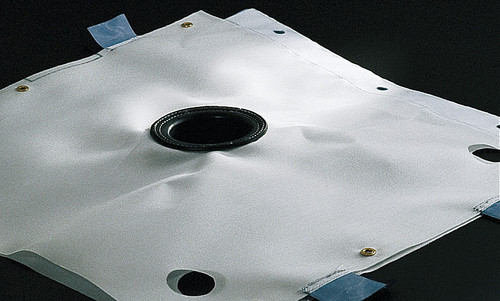

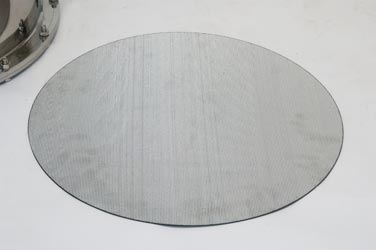

Filter Press Panel Cloth

We are one of the leading manufacturers and suppliers of a comprehensive range of Filter Press Cloth Panel. These are manufactured using non-woven and woven filter media, which are sourced from certified vendors in the market. The filter media is being sourced as per our high accuracy standards from certified fabric manufacturers. We also provide our range in various sizes and dimensions that meet the individual requirement of our clients. It is widely used in various industries like pharmaceuticals, chemicals, food and beverages, leather etc.

Specifications:

- For, Plate Size (Round) : 18"� Dia , 24" Dia, 30" Dia, 32"� Dia, 36" Dia

- For, Plate Size(Square) : 30"x 30"�, 32"�x 32"�, 36"x 36"�, 40"�x 40"�, 42"�x 42"�, 48"�x 48" & 60"x 60"� inches

- Filter Press Pcs. for Wooden filter press, Cast iron filter press, PP filter press, Recess filter press, Membrane filter press etc

Applications:

- Chemicals

- Fertilizer Plants

- Pharmaceuticals

- Food and Beverages

- Ceramic Industries

- Steels and Alloys Industries

- Pesticides and Agro Chemicals Plants

- Effluent and Suez Treatment Plants (ETP and STP)

Centrifuge Filter Bags

An ample range of qualitative Centrifuge Filter Bags is provided by us, which mainly includes lifting type bags, collar and without collar type centrifuge bags. Our clients can avail from us a unique range of Centrifugal Filter Bag. This bag is fabricated using high grade cloth that is sourced from known and trusted fabric manufacturers. It is widely used in various industries and is highly appreciated by the clients for its durability and long service life. We are widely well reckoned as one of the predominant industrial centrifuge bags manufacturers, based in Gujarat. These centrifuge bags are available in various sizes and dimensions. They are immensely used in various industries like fertilizer, bulk drugs, food processing industries etc.

Features:

- Lifting type bottom discharge with lifting hooks CF bag.

- Collar type CF bag

- Without collar type CF bag.

- Size�:�20, 24, 30, 36, 48, 60 Inches

Applications:

- Chemicals and Pharmaceuticals Industries

- Fertilizer Industries

- Food Processing Industries

- Bulk Drugs Industries

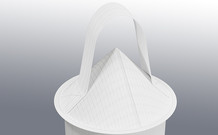

Fluid Bed Dryer Filter Bags

We offer a vast range of unmatched Fluid Bed Dryer (FBD) Filter Bags, which are easily available in different sizes as per the client requirement and standard OEMs. These dryer bags exhibit various top-ranking properties in a cost-effective manner. The entire assortment of FBD bag is manufactured using qualitative fabrics sourced from trusted fabric manufacturers. We supply these bags to various industrial applications like pharmaceuticals, food processing, pharmaceuticals, and additives. We bring these ranges in bulk for our customers with economical rates. We offer these Fluid Bed Dryer Bags at competitive market prices all over. We understand the requirement of our esteemed client and manufacture these Fluid Bed Dryer Bags in order to fulfil their requirements.

Features:

- Different bags different products are strongly recommended depending on required air permeability, retention micron and static charge.

- Size�:�5 Kg. (Lab Model), 30, 60, 120, 250, 500 Kg. As per standard OEMs and customers requirements.

Applications:

- Pharmaceuticals Industries

- Chemical Industries

- Agriculture Industries

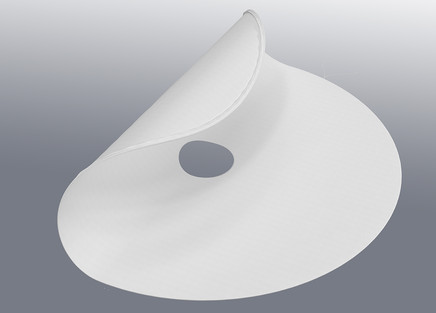

Nutsche Filter Bags

We offer a high quality of Nutsche Filter Bags which are used for separating the solid from the liquid and these products are manufactured and supplied to the customers all over in India. These products have been made using a high quality of raw materials and they have a very precise make which ensures a long service life to the customers. Our products have been priced at very reasonable rates in the market.. The agitated Nutsche Filter Bags consist of a cylindrical shell with top dished and welded flat bottom. The base plate is stiffened by supports welded under the base plate. The base plate is having arrangement of bolting bar to hold the filter cloth. Suitable support mesh is provided under filter cloth to facilitate the flow of the filtrate.

We are manufacturer of nutsche filter cloth from PP, Polyester, Nylon, Cotton and HDPE cloth. We make Agitated, Non-agitated nutsche filter cloth in shape of round, square and rectangular. We offer nutsche filter cloth as per standard as well as custom design and drawing. It can be�used for filtration of chemicals, pharmaceuticals products, Agro-fertilizers and minerals etc.

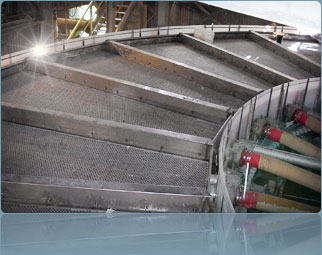

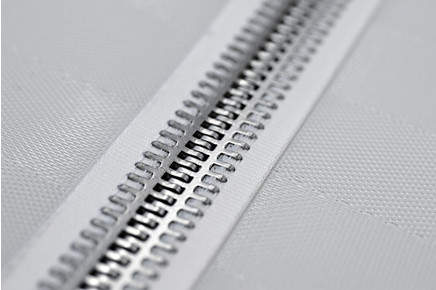

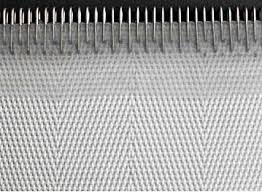

RVDF Filter Cloth

Rotary Vacuum Drum Filters (RVDF) operates under high vacuum with a drum which rotates in a pan. However, the filter cloth comes off the drum and travels to a discharge system such as doctor blade, cooch (helix) roll or gravity. After back wash, the clothes return to the pan to repeat the process. The RVDF filter cloth is held on the drum with edge guides using rope, coil springs or molded rubber (PIP) edging. Typical cloth closures are manual sewing, velcro, clipper lacing or zippers (or a combination of those methods).

Product Images

Copyright © 2022 Filtron Techniques